Robust permeable hierarchical strusctures via freeze casting and assembly of BCP

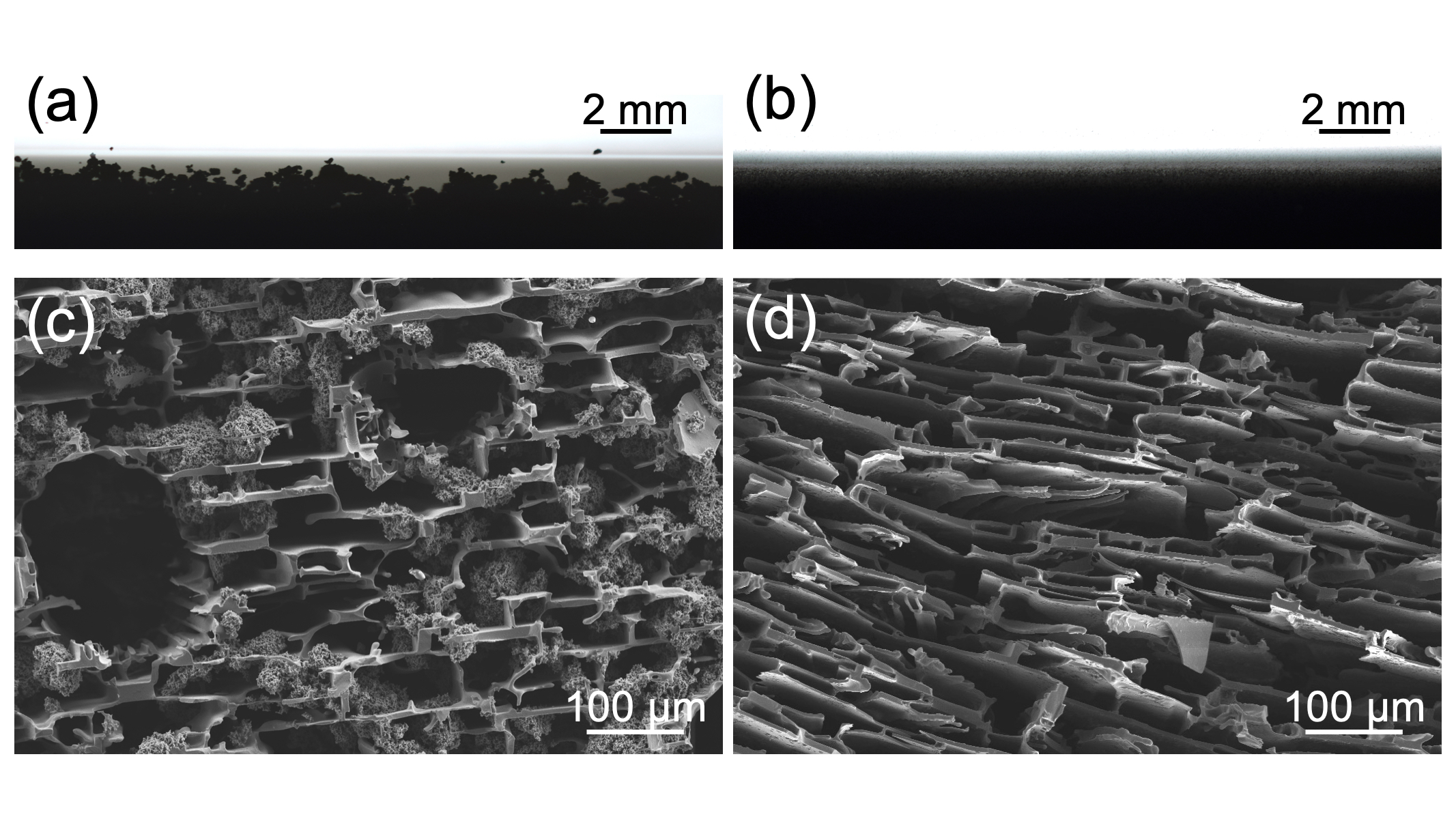

Porous ceramics are largely used for filters and catalyst supports due to their chemical and temperature stability. Three characteristics are particularly crucial for these applications: surface area, permeability, mechanical robustness. High surface area allows more active sites for chemical reactions or capture. High permeability promotes fluid transport to reaction/capture sites. Mechanical robustness ensures prolonged product life. However, optimizing structures for surface area, permeability, mechanical robustness remains a challenge as they are often inversely related to one another through porosity and pore size. To address this challenge, we propose a porous composite with two structural elements: The first is a SiOC template with dense pore walls produced by freeze casting of preceramic polymers. Micrometer pores provide rapid fluid transport and low back pressure. By re-infiltrating with a fugitive phase of self-assembled triblock copolymers, an interior surface coating of SiOC adds porosity of a second length scale. The derived nanometer pores provide high surface area. Evolution of the hierarchical structure was investigated with X-ray tomography. The surface area, porosity, mechanical and flow properties were examined to provide an understanding of how complex structures influence material response and to assess the composite’s potential as a filtration material. Read More...

Carbon nanotube-reinforced silicon oxycarbide via freeze casting

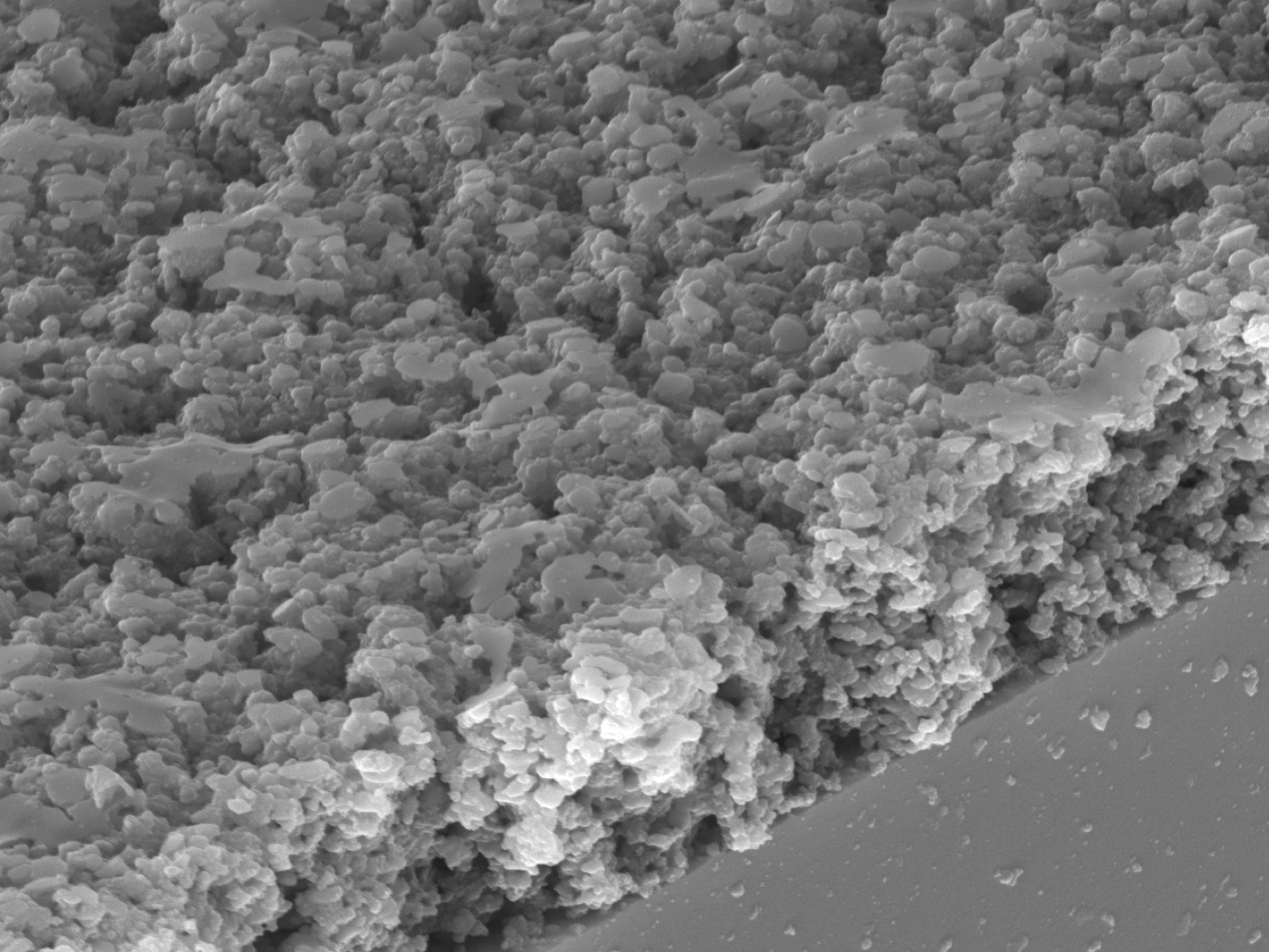

Reinforcement strategies were applied to solution-based freeze-casting systems to form porous ceramic composites. Multi-walled carbon nanotubes (MWCNT) were used as the reinforcing fillers in a polysiloxane preceramic polymer freeze cast with dimethyl carbonate to produce silicon oxycarbide-based lamellar pore structures. Using a carefully designed dispersion procedure, CNT agglomerates were reduced both in suspension and in pore walls. Electrical conductivity increased by ten orders of magnitude over pure silicon oxycarbide, indicating the preservation of CNTs after pyrolysis. Permeability, compression, and diametral compression (Brazilian disk) tests were performed to demonstrate the reinforcing effect of CNTs without sacrificing the permeability of the final porous structures.

Publication: Kuo, C., & Faber, K. (2020). Permeable carbon nanotube-reinforced silicon oxycarbide via freeze casting with enhanced mechanical stability. Journal of the European Ceramic Society, 40(6), 2470-2479. doi:10.1016/j.jeurceramsoc.2019.12.059

Theorctical and experimental investigations of particle engulfment during solidification

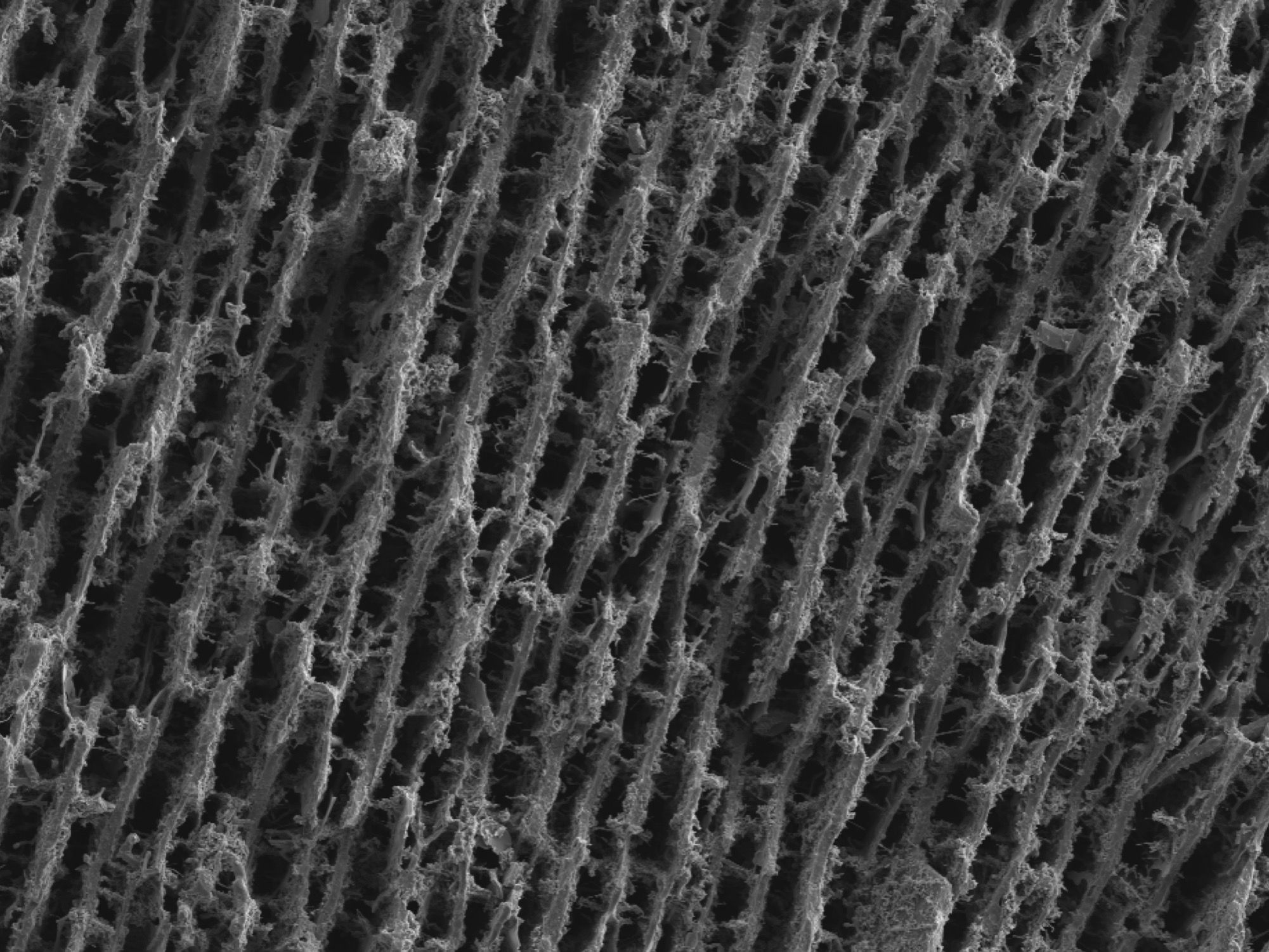

Strength and permeability are two critical characteristics for porous ceramics that are used as filters or supports for catalyst. The ideal filters and supports must be sufficiently durable to withstand the fluid pressure while allowing for rapid fluid transport. However, it is difficult to achieve the combination of strength and high permeability in the same system. One approach to optimize the pair is by reinforcing a highly permeable structure, in this case, a lamellar pore structure, with inter-lamellar wall bridges produced by dispersing high-aspect ratio particles in a freeze-casting solution. According to particle engulfment theories, particles sizes larger than a critical radius will be engulfed instead of being pushed away by the freezing front to the pore wall. However, most particle engulfment theories fail to explain partial engulfment with respect to the alignment of high-aspect ratio particles. To remedy these deficiencies, we propose a modified particle engulfment model. The model takes into the account angles and positions of the high-aspect ratio particles with respect to the freezing dendrites. Theoretical predictions from the modified model are compared with the experimental results of SiC whisker-reinforced SiOC produced via freeze casting of polysiloxane preceramic polymer solutions. Read More...